The transformer winding deformation tester, utilizing the frequency response analysis (FRA) method to detect mechanical structural changes in the winding, possesses notable technical advantages, particularly excelling in non-destructive testing, high sensitivity, and rapid convenience. Detailed explanations of its core strengths are as follows: 1. Non-destructive testing to avoid secondary damage. ① No need to disassemble the transformer. Traditional testing methods require disassembly of the transformer, which is time-consuming and may introduce new faults (such as insulation damage or sealing failure).

The winding deformation tester can complete the detection through external wiring, without touching the internal structure of the winding throughout the process, completely avoiding the risk of secondary damage.

② The applicable scenarios are wide, including factory tests, handover tests, preventive tests, and post-fault diagnosis, especially suitable for regular condition assessment of transformers in operation.

For example, in the field of substations, rapid detection of transformers subjected to short-circuit impact can determine whether the windings are deformed without the need for power outages and disassembly.

2. High sensitivity, capturing minute deformations ① With a detection accuracy down to the millimeter level, the tester can detect mechanical deformations (such as axial displacement and radial distortion) in windings, which alter distributed parameters like inductance and capacitance. It can detect minute deformations down to the 0.1mm level.

② Early fault warning: At the early stage of inter-turn short circuit or insulation aging, winding deformation may not yet cause obvious electrical faults (such as abnormal oil chromatography), but the tester can already issue an early warning through changes in the frequency response curve.

3. Fast and convenient, suitable for on-site use. ① With a short single test time and a frequency sweep range of 1kHz~2MHz, a single test with 1000 test points takes only 3~5 minutes, which is much faster than traditional methods (such as the low-voltage pulse method, which takes more than 10 minutes).

Comparison: The hood inspection requires power outages lasting from several hours to several days, whereas the tester can complete the inspection online or with short-term power outages.

② The operation is simple, the results are intuitive, and the instrument has a high degree of automation. Operators only need to connect the test lines and set parameters (such as frequency range, number of scanning points) to automatically generate the logarithmic amplitude-frequency characteristic curve.

Result determination: By comparing the historical curve or standard template, deformation can be determined if the correlation coefficient (R) is less than 0.9 or the resonance peak shift (Δf) exceeds 5%, without requiring complex calculations.

4. Data traceability, supporting long-term tracking and analysis. ① Storage and export functions: The instrument is equipped with a large-capacity internal memory, capable of storing hundreds of test curves, and supports exporting data to a computer via a USB flash drive, facilitating the establishment of transformer health records.

② Multi-dimensional data fusion analysis can integrate results from oil chromatography analysis, infrared temperature measurement, partial discharge detection, and other methods to comprehensively determine the cause of deformation (such as short-circuit impact, overload, transportation collision).

5. Strong anti-interference capability and adaptability to complex environments. The electromagnetic compatibility design incorporates technologies such as shielded cables and filtering circuits, effectively suppressing on-site electromagnetic interference and ensuring the stability of test data.

② Wide environmental adaptability: Operating temperature range of -10℃~50℃, humidity ≤95%, suitable for harsh environments such as plateaus, deserts, and coastal areas.

6. Economic and Safety Advantages: ① Reduced Operation and Maintenance Costs. Early detection of winding deformation can prevent the escalation of faults and minimize unplanned outage losses. Statistics show that after using the tester, the transformer failure rate has decreased by 30%, and the average repair time has been shortened by 50%.

② The operating safety test voltage is low (usually ≤10V), posing no electric shock risk to operators and eliminating the need for work at height (such as high-voltage bushing inspection), thus meeting safety regulations.

Summary: The transformer winding deformation tester, with its core advantages of non-destructive testing, high sensitivity, speed and convenience, and data traceability, combined with strong anti-interference capability and cost-effectiveness, has become the preferred tool for transformer condition assessment. It is not only suitable for rapid on-site diagnosis but also enables preventive maintenance through long-term tracking analysis, significantly enhancing the reliability of power grid operation and reducing operation and maintenance costs.

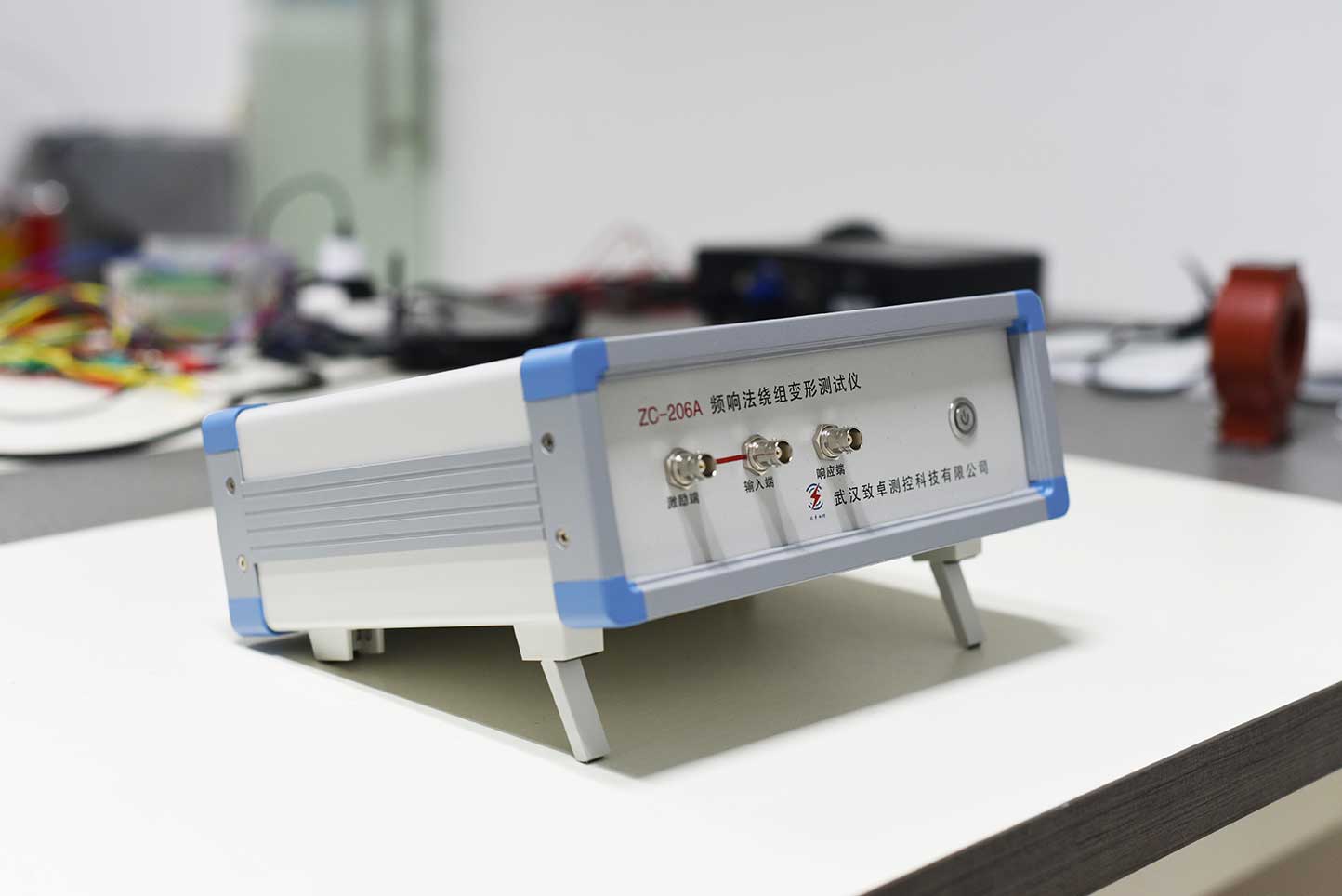

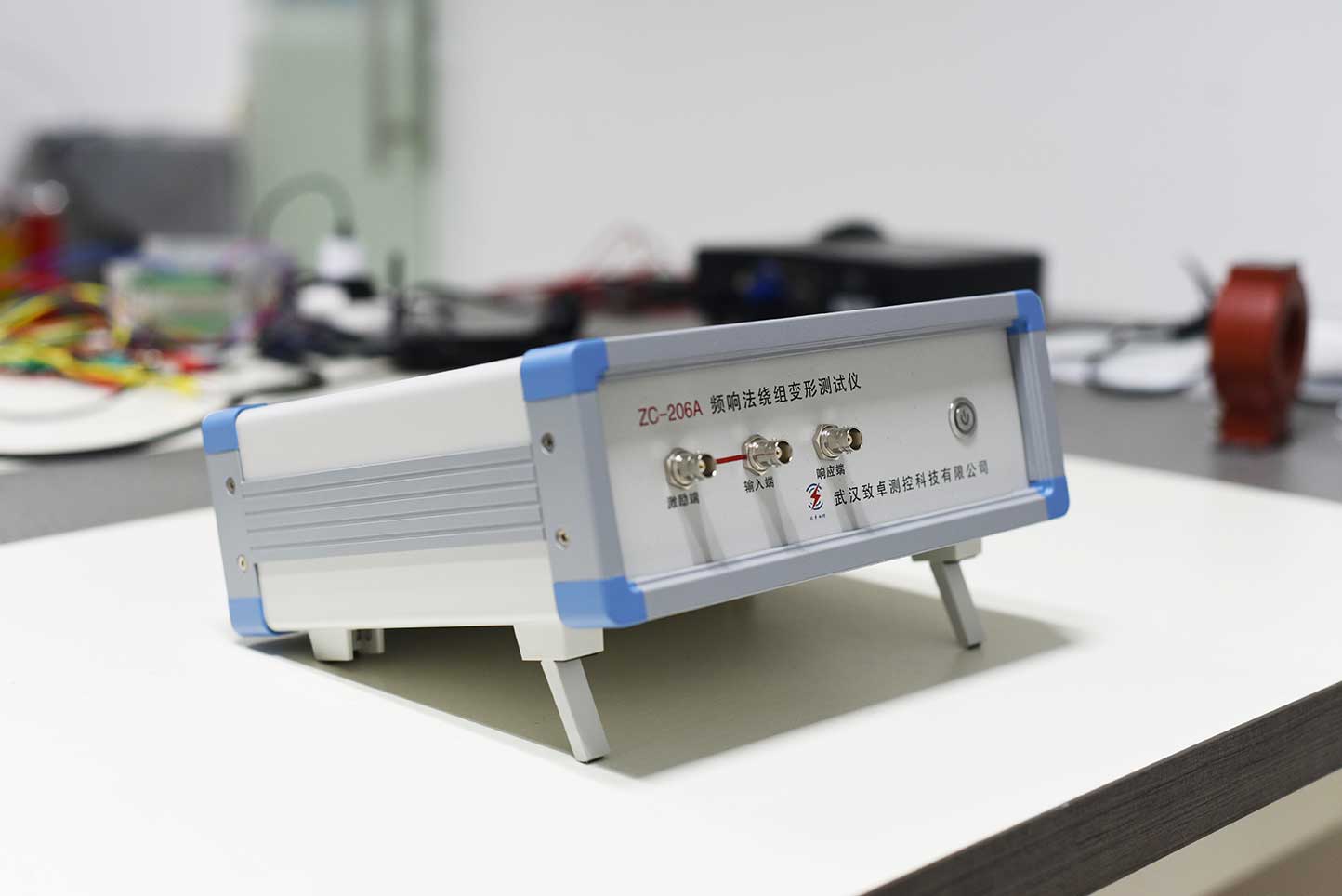

ZC-206A transformer winding deformation tester detects the amplitude frequency response characteristics of each winding of the transformer, compares the detection results vertically or horizontally, and judges the possible deformation of the transformer winding according to the change degree of amplitude frequency response characteristics.

Kvtester Electronics Technology Co.,Ltd. is a high-tech enterprise specializing in power testing, testing, research and development, production, and sales of testing equipment. It has been engaged in the electrical testing industry for many years, and its products are of high quality. We welcome customers to come and purchase. Service hotline: 0086-27-81778799, to learn more, visit the official website: www.kvtester.com