The transformer comprehensive test bench is a specialized equipment used for electrical performance testing of power transformers. It integrates test wiring display, data acquisition, analysis and processing, measurement control, storage and printing, and protection functions. It can efficiently and accurately complete multiple core parameter tests and is widely used in the fields of power equipment manufacturing, testing, and substations. During the use of the transformer comprehensive test bench, in order to ensure the safety of personnel and equipment, the following safety precautions must be strictly followed:

1. Preparation before operation

① Reading manual: Before use, it is necessary to carefully read the operating manual, familiarize oneself with the equipment performance, technical parameters, and operating procedures.

② Personnel qualifications: Operators should possess electrical knowledge and operational skills, hold certificates for employment, and receive necessary safety training.

③ Environmental inspection: Ensure that the testing environment is dry and tidy, avoiding places such as rain, corrosive gases, excessive dust, high temperatures, and direct sunlight.

④ Equipment inspection: Check that the appearance of the test bench is undamaged, all components are securely connected, the instrument display is normal, and the grounding resistance meets the standard (≤ 4 Ω).

⑤ Preparation of test sample: Conduct a visual inspection of the test transformer to confirm that there are no abnormalities; Disconnect the connection with the lead before measurement, and there should be a clear disconnection point; Fully discharge to prevent residual charges from injuring people.

2. Safe operation

① Personal protection: Operators must wear protective equipment that complies with regulations, such as insulated gloves, insulated shoes, safety helmets, protective goggles, etc.

② High voltage operation:

a. Strictly follow the operating procedures to conduct high-voltage tests and ensure the safety of equipment and personnel.

b. Before applying pressure, carefully check the test wiring to confirm that the scale, range, regulator zero position, and initial state of the instrument are correct and error free.

c. Notify relevant personnel to leave the tested equipment and obtain permission from the person in charge of the experiment before applying pressure.

d. During the pressurization process, there should be supervision, and the operator should stand on an insulating pad, concentrate their energy, and not chat with others.

③ Wiring and movement:

a. During the testing process, it is prohibited to move the test clamp and power supply line to prevent arc discharge or electric shock.

b. When disconnecting equipment connectors for testing purposes, markings should be made before disassembly, and wiring should be checked and calibrated.

④ Exception handling:

a. If any abnormalities occur during the test (such as arc, leakage, abnormal sound, or burnt smell), the test should be stopped immediately, the power should be disconnected, and necessary repairs and treatments should be carried out.

b. During the process of conducting a DC leakage current test, if it is found that the leakage current increases sharply with time or there is abnormal discharge, the test should be stopped immediately and the power supply disconnected. The tested transformer winding should be grounded and fully discharged before inspection.

3. Special testing scenarios

① Test of no-load voltage regulating transformer:

a. When measuring an unloaded voltage regulating transformer, be sure to wait for the discharge indicator alarm sound to stop before switching gears.

b. It is not allowed to switch the no-load tap changer during the testing process or before discharging the power.

② Sensitivity test object testing:

a. It is not allowed to remove the test line without fully discharging (when the buzzer sounds) to avoid electric shock.

③ External power outage handling:

a. During the testing process, if there is a sudden power outage of external AC220V, the instrument will start to discharge automatically. At this time, it is not allowed to immediately dismantle the test line. You need to wait for 5 minutes before dismantling the line.

4. Post operation maintenance

① Discharge and power outage:

a. After the test is completed, be sure to wait for the discharge alarm to stop before turning off the power and removing the test line.

b. The tested winding must be fully discharged to prevent residual charges from injuring people.

② Equipment inspection and cleaning:

a. Conduct a comprehensive inspection of the equipment and instruments to confirm that there is no damage or abnormality before returning to their original position.

b. Clean up the test site, remove debris and flammable materials, and keep the site clean and safe.

③ Data recording and storage:

a. Record the experimental data accurately, including the temperature of the tested equipment and relevant information such as the temperature and humidity of the surrounding environment.

b. Properly preserve test records and data for future reference and analysis.

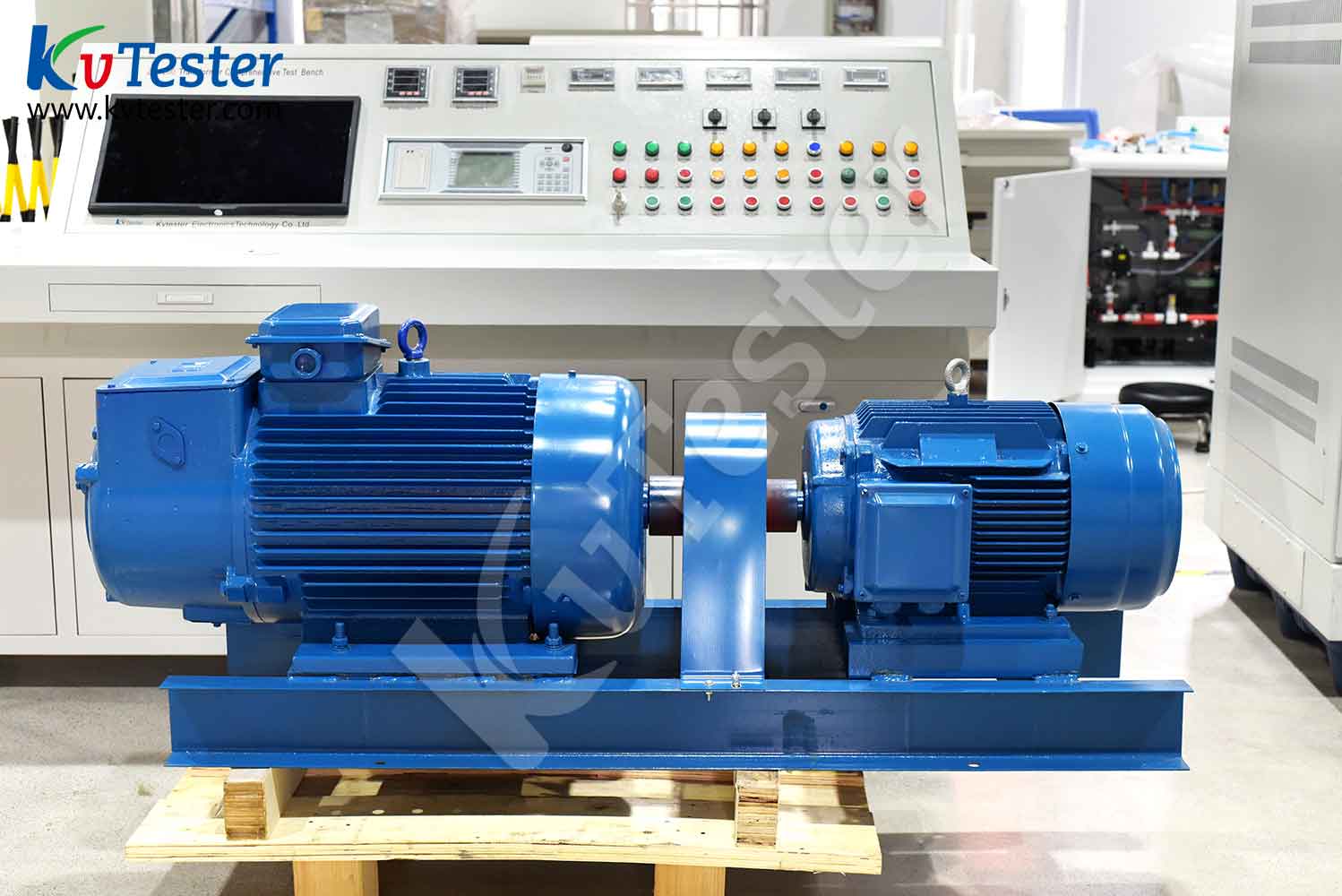

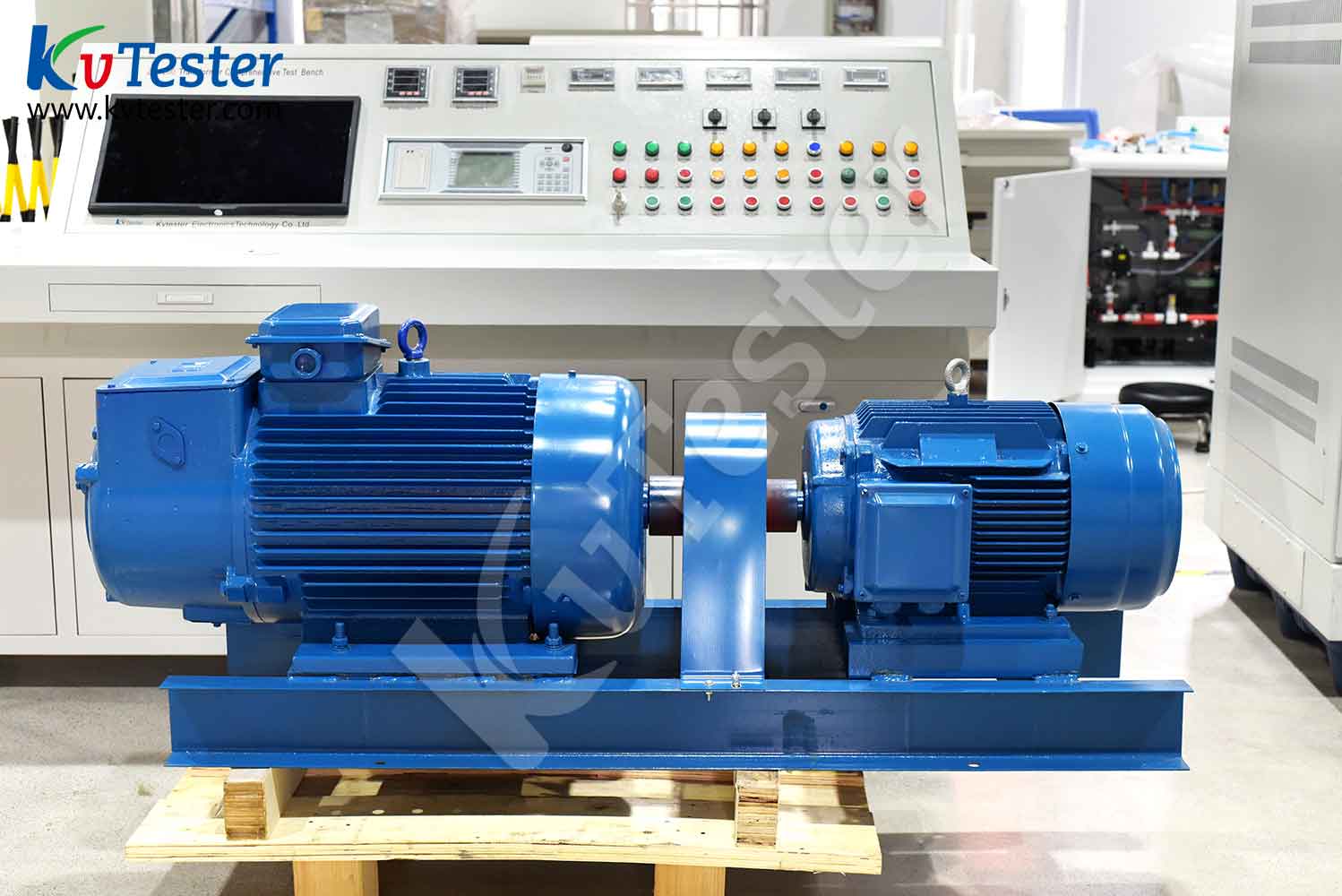

ZC-200 transformer comprehensive test bench is mainly used to test the no-load and load characteristics of power transformers and distribution transformers, and can also perform frequency doubling induction and power frequency withstand voltage tests on the tested transformers. The measuring part of the device is controlled by a high-end microcontroller, and the digital display, no-load, short circuit and other test data are synchronously sampled by the microcontroller, avoiding the errors caused by manual calculation of voltage, ammeter and power meter readings in traditional testing methods. This equipment is suitable for factory and routine testing of three-phase transformers with a capacity of 5000kVA/36.2-13.2KV and below in the production and maintenance departments of power transformers.

Kvtester Electronics Technology Co.,Ltd. is a high-tech enterprise specializing in power testing, testing, research and development, production, and sales of testing equipment. It has been engaged in the electrical testing industry for many years, and its products are of high quality. We welcome customers to come and purchase. Service hotline: 0086-27-81778799, to learn more, visit the official website: www.kvtester.com