The selection suggestions for the fully automatic oil dielectric breakdown voltage tester are as follows:

1. Clearly define testing requirements and standards

① Voltage range

a. Conventional requirement: Select instruments in the range of 0-80kV, suitable for most transformer oil and circuit breaker oil detection.

b. Special requirements: If testing ultra-high voltage equipment (such as transformers above 110kV) is required, the 0-100kV expansion model can be selected (customized).

c. According to the standard: Ensure that the instrument complies with GB/T 507-2002 "Determination of breakdown voltage of insulating oil" or IEC 60156, and supports the boost rate specified in the standard (such as 2kV/s or 3kV/s).

② Test object and medium

a. Liquid media: instruments that support liquid detection such as insulation oil, transformer oil, circuit breaker oil, and capacitor oil should be preferred.

b. Solid medium: If testing solid materials (such as resins and plastics), a multifunctional device that supports gradient boosting or pressure resistance testing should be selected.

2. Comparison of core performance parameters

① Accuracy and stability

a. Voltage accuracy: Select instruments with ± 1% or ± (2% x reading+0.2kV) to ensure data reliability.

b. Repeatability: Priority should be given to selecting equipment with a small range of 6 tests (such as Wuhan ultra-high voltage products) to reduce human error.

c. Boosting rate: Supports multi speed adjustment of 1.0, 2.0, and 3.0 kV/s to meet different standard requirements.

② Functional characteristics

a. Automation level:

Fully automatic mode: supports 6 consecutive experiments and automatically calculates the average value, reducing manual operation.

Single mode: suitable for fast single detection.

b. Mixing and settling: Equipped with a built-in magnetic mixing system and automatic settling function, ensuring the uniformity of the oil sample.

c. Data Management: Supports storing over 100 sets of data and can export PDF reports (including testing time, environmental temperature and humidity, and operator information).

③ Security protection

a. Multiple protection: It has protection functions such as overvoltage, overcurrent, short circuit, and grounding to prevent equipment or sample damage.

b. High voltage interlock: During the testing process, the high voltage compartment door automatically locks and opens to cut off power.

c. Emergency stop button: Quickly cut off power in case of emergency.

3. Equipment configuration and scalability

① Electrode and oil cup

a. Electrode form: Standard flat electrode, gap 2.5mm (adjustable), suitable for different oil sample thicknesses.

b. Oil cup capacity: Choose 400ml or 200ml capacity to meet batch testing needs.

c. Material: The electrode is made of stainless steel, which is corrosion-resistant and easy to clean.

② Environmental adaptability

a. Working temperature: Supports 0 ℃ to 40 ℃, suitable for laboratory or on-site environments.

b. Protection level: The shell reaches IP54, dustproof and waterproof, suitable for temporary testing points in workshops or substations.

c. Power supply: Supports AC 220V ± 10%, built-in large capacity lithium battery (optional), suitable for environments without external power supply.

③ Extended functionality

a. External device: Supports exporting data from a USB flash drive or RS232/USB interface, connecting to a computer for data analysis.

b. Multi language interface: Chinese menu guidance for easy operation.

c. Compatibility: Compatible with national standard 2002 and 1986 versions for testing, with custom testing conditions.

4. After sales service

① Training support: Provide free operation training and standard interpretation.

② Long term maintenance: supports remote diagnosis, software upgrades, and regularly pushes oil maintenance knowledge.

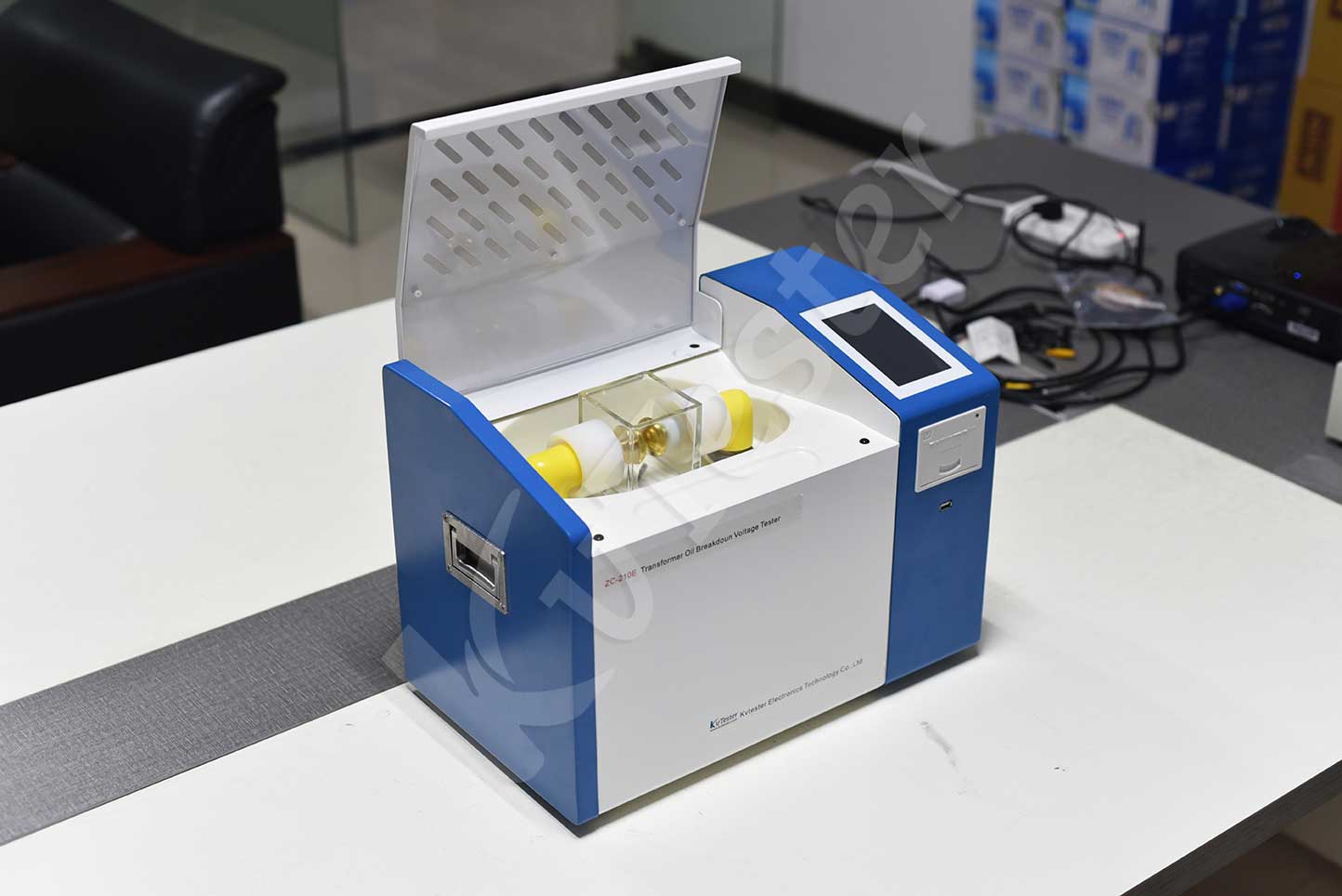

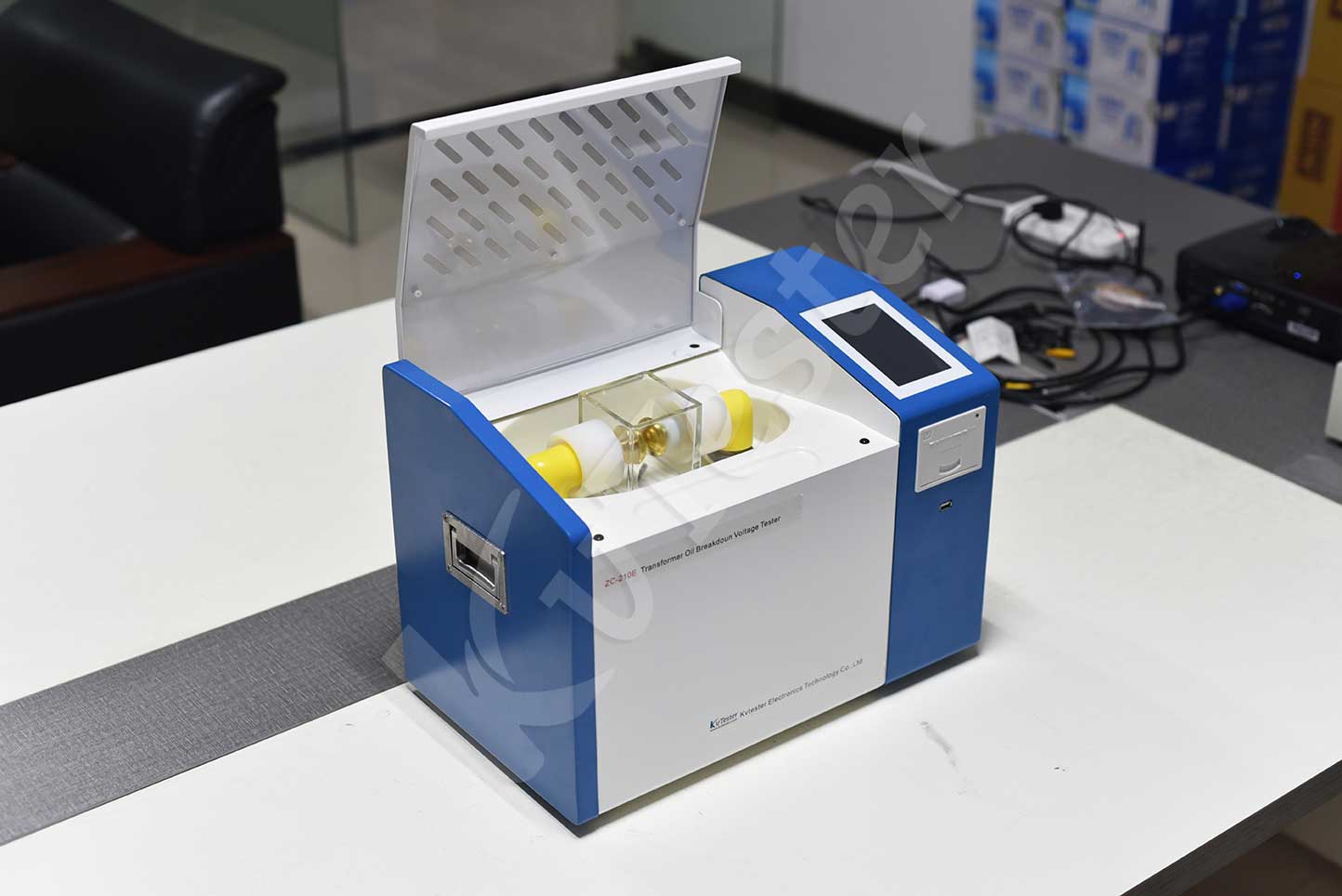

Many power systems, railway systems, large-scale petrochemical plants and enterprises have a lot of electrical equipment whose internal insulation are mostly oil-filled insulation type, and therefore, test on insulating oil dielectric strength is common and necessary. This instrument, by using a single-chip microcomputer as the core, can operate in full automation with high accuracy, greatly improving work efficiency and reducing the labor intensity of workers. Moreover, it is small in size and convenient to carry.

Kvtester Electronics Technology Co.,Ltd. is a high-tech enterprise specializing in power testing, testing, research and development, production, and sales of testing equipment. It has been engaged in the electrical testing industry for many years, and its products are of high quality. We welcome customers to come and purchase. Service hotline: 0086-27-81778799, to learn more, visit the official website: www.kvtester.com