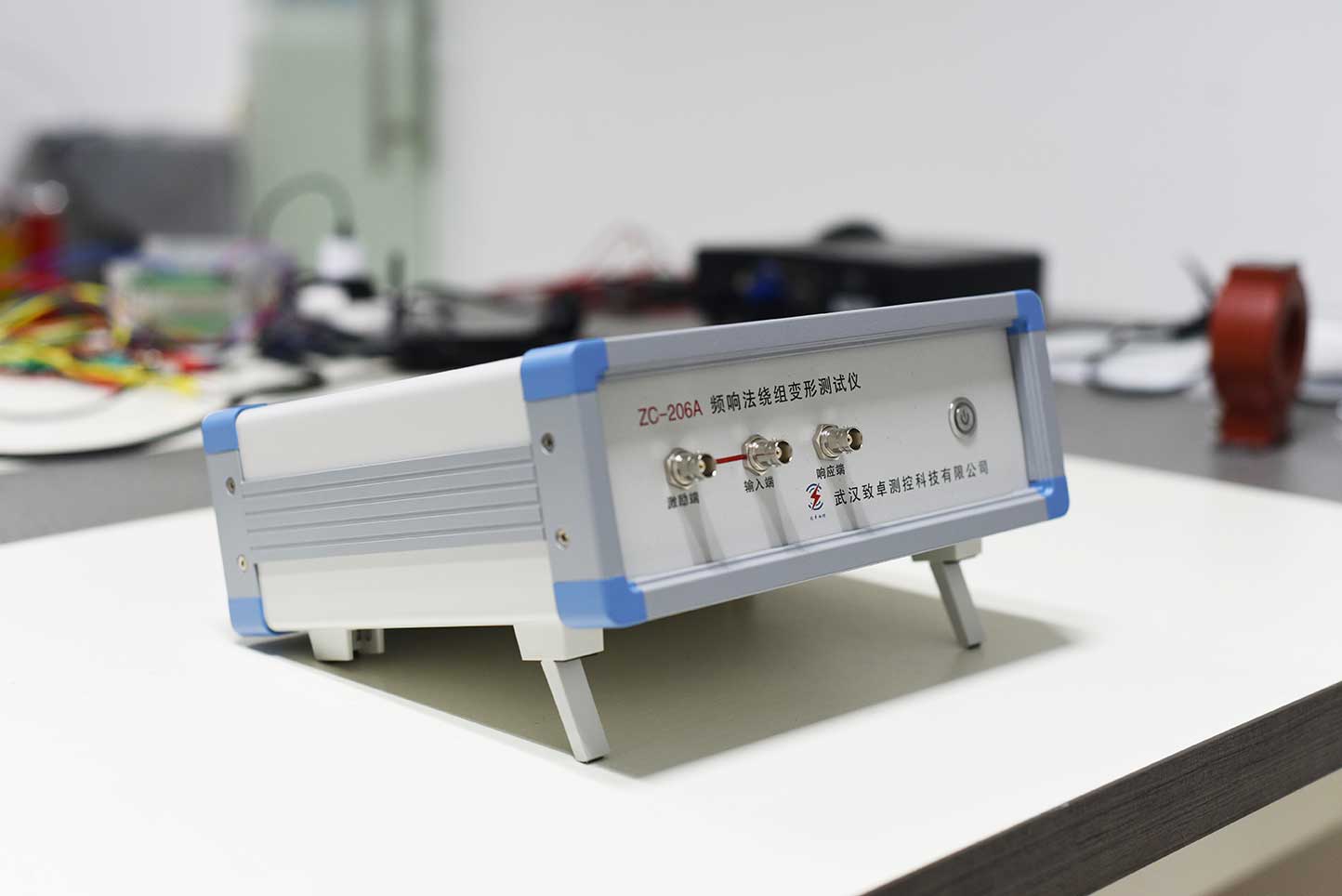

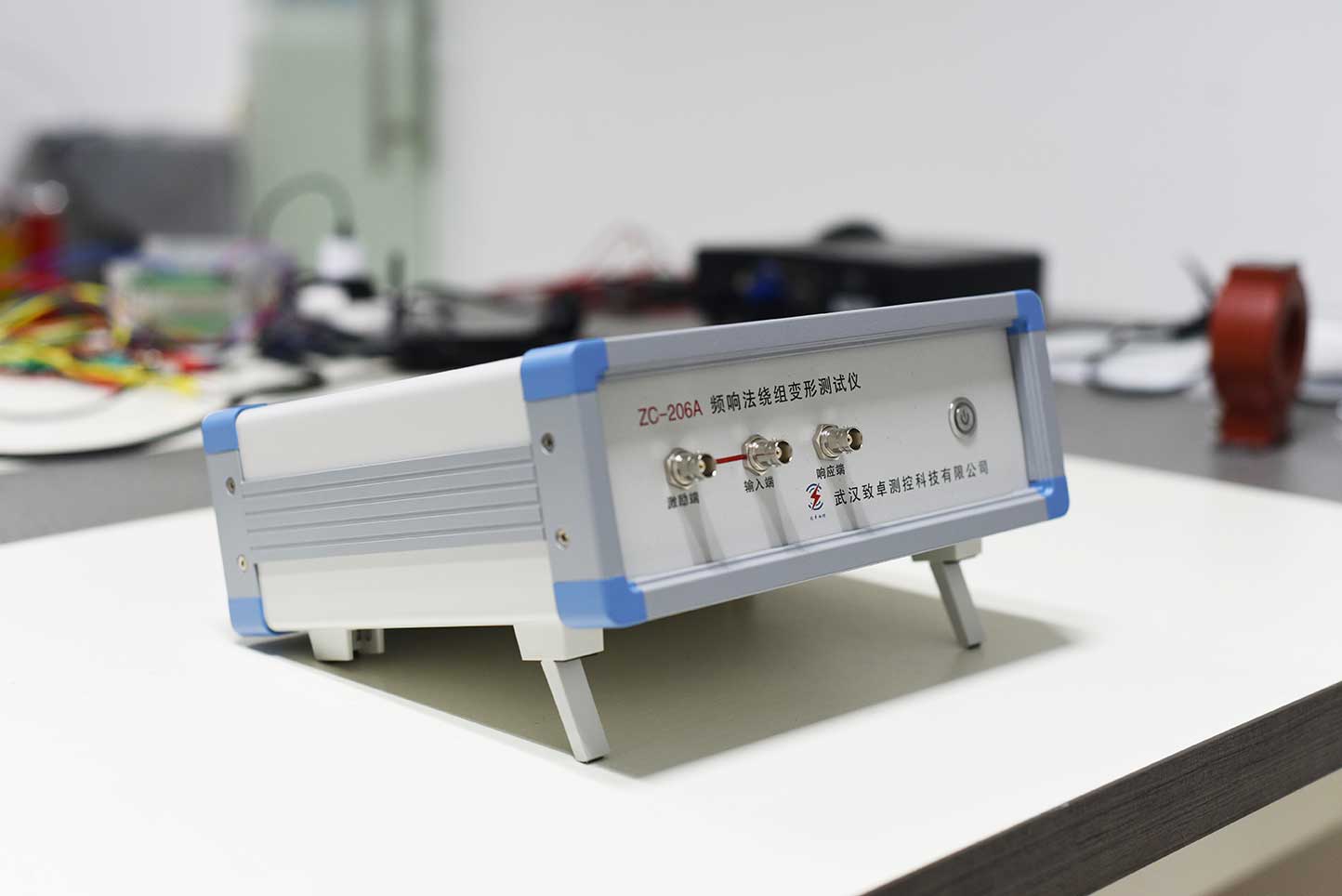

The transformer winding deformation tester quantitatively evaluates the mechanical state of the winding through frequency response analysis (FRA), and is suitable for the following specific scenarios, covering the full life cycle management requirements of the equipment. The following analysis is conducted according to the application scenario classification, detection purpose, typical cases, and technical advantages:

1. Scenario of Transformer Lifecycle Management

① Factory inspection and quality control

Scenario: During the production and manufacturing stage of transformers, it is used for mechanical performance verification of windings before leaving the factory.

a. Purpose of testing:

Verify whether the winding design parameters (such as inter cake distance and strut tightness) meet the standards;

Identify manufacturing defects (such as wire bending, interlayer insulation damage).

b. Technical advantages:

Comparison between frequency response curve and theoretical model shows an accuracy of ± 0.1dB;

Automatically generate testing reports that comply with the GB/T 1094.7 standard.

② Transport impact damage detection

Scenario: After long-distance transportation of transformers (such as bumpy road sections by sea or land).

a. Purpose of testing:

Quantify the displacement of windings caused by vibration and impact during transportation;

Prevent post operation malfunctions caused by hidden damage.

b. Technical advantages:

Portable devices support rapid on-site testing (single-phase testing ≤ 3 minutes);

Comparative analysis of historical data (such as warning if the deviation rate of frequency response curve before and after transportation is greater than 3%).

③ Preventive testing and condition based maintenance

Scenario: Regular maintenance cycle for transformers (such as once every 3-5 years).

a. Purpose of testing:

Monitor the trend of mechanical performance degradation of windings;

b. Technical advantages:

The database supports multi cycle frequency response curve overlay analysis;

The trend prediction algorithm can provide a warning of deformation risk 6-12 months in advance.

④ Post fault diagnosis and repair verification

Scenario: After the transformer is subjected to faults such as short-circuit impact and lightning strikes.

a. Purpose of testing:

Quickly locate the type of winding deformation;

Verify the effectiveness of the repair plan.

b. Technical advantages:

Support synchronous testing of three-phase windings;

The AI assisted diagnostic system can recognize 12 typical deformation patterns.

Kvtester Electronics Technology Co.,Ltd. is a high-tech enterprise specializing in power testing, testing, research and development, production, and sales of testing equipment. It has been engaged in the electrical testing industry for many years, and its products are of high quality. We welcome customers to come and purchase. Service hotline: 0086-27-81778799, to learn more, visit the official website: www.kvtester.com