Transformer winding deformation is a key hidden danger that affects the safe operation of equipment. Its testing methods can be divided into three mainstream technologies: frequency response analysis (FRA), short-circuit impedance method (SCI), and low-voltage pulse method (LVI), and have derived supplementary methods such as vibration signal analysis and ultrasonic testing. The following is a systematic analysis from the dimensions of technical principles, applicable scenarios, and comparison of advantages and disadvantages:

1. Frequency response analysis (FRA) - high-precision detection of "fingerprint features"

① Technical principles

Inject a sine signal into the winding through frequency sweep excitation (1kHz~2MHz), measure its transfer function (amplitude frequency/phase frequency response), and form a frequency response curve similar to a "fingerprint". Winding deformation can cause resonance point displacement or amplitude changes, and diagnosis can be achieved by comparing historical curves.

② Typical application scenarios

Fault diagnosis: Identify deformation modes such as axial displacement, radial distortion, and turn to turn short circuit

Trend analysis: Predicting the degradation trend of windings through the superposition of multi period curves

Live detection: cooperate with high-voltage isolation sensors to achieve uninterrupted detection (such as ± 800kV converter transformer)

2. Short circuit impedance method (SCI) - traditional method "stiffness index"

① Technical principles

Measure the short-circuit impedance (Zsc) of the transformer winding and evaluate the geometric size changes of the winding through the impedance change rate (Δ Z%).

② Typical application scenarios

Factory acceptance: As a mandatory item for transformer factory testing

Regular maintenance: comparative analysis with handover test data

Emergency assessment: Quickly determine whether the winding is deformed after a fault occurs

3. Low Voltage Pulse Method (LVI) - Early Detection of "Pulse Response"

① Technical principles

Inject low-voltage pulses (below 100V) into the winding and measure the degree of distortion in the reflected waveform. The normal winding reflection wave exhibits attenuation oscillation, and deformation can cause waveform distortion or reflection time delay.

② Typical application scenarios

Factory test: detect manufacturing defects in windings

Transportation monitoring: Evaluating the impact of transportation shocks on windings

Equipment with missing historical data: Replace FRA to establish benchmark curve

4. Supplementary testing techniques

① Vibration signal analysis method

Principle: Collect vibration signals of transformer core/winding through sensors, analyze changes in spectral characteristics

Advantages: Real time monitoring, suitable for online diagnosis

Limitations: susceptible to interference from load current and cooling system vibration

② Ultrasonic testing method

Principle: Utilizing the propagation characteristics of ultrasonic waves in winding insulation to detect internal defects

Advantage: Can locate partial discharge or insulation damage

Limitations: Power outage detection required, complex operation

Summary: Transformer winding deformation detection requires selecting appropriate methods based on equipment type (voltage level, capacity), operating conditions (whether live or not), and detection purpose (rapid screening/accurate diagnosis).

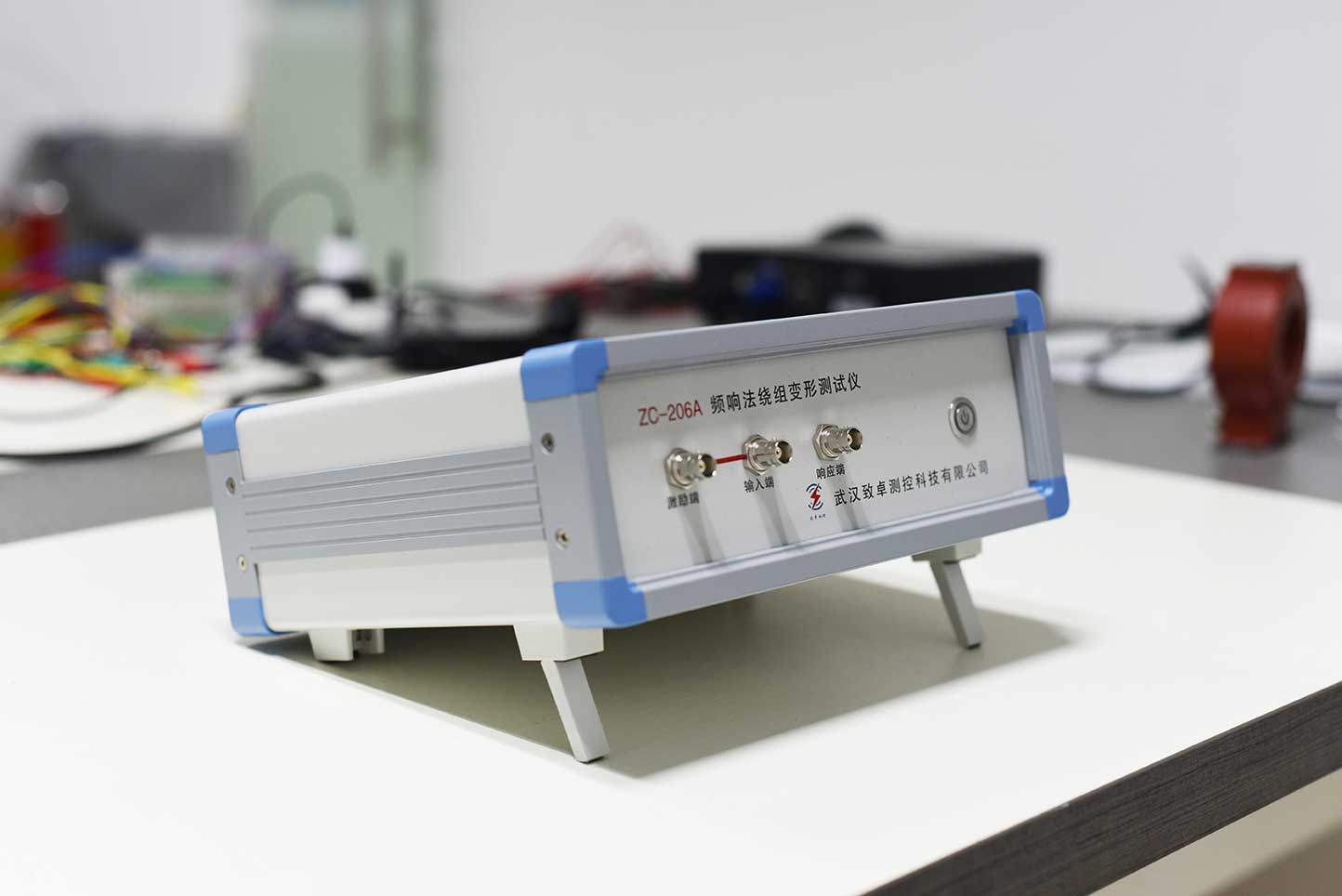

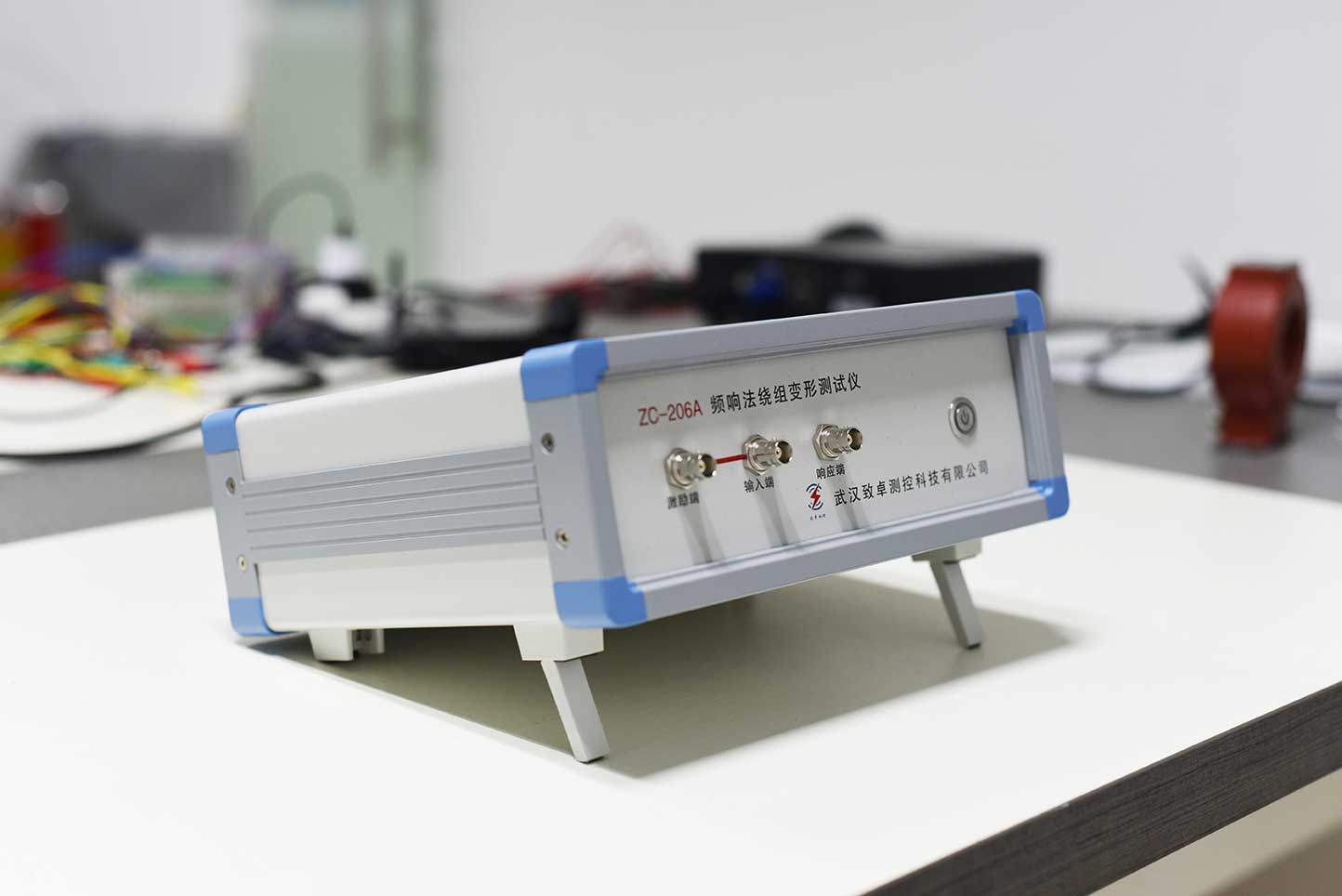

ZC-206A transformer winding deformation tester detects the amplitude frequency response characteristics of each winding of the transformer, compares the detection results vertically or horizontally, and judges the possible deformation of the transformer winding according to the change degree of amplitude frequency response characteristics.

Kvtester Electronics Technology Co.,Ltd. is a high-tech enterprise specializing in power testing, testing, research and development, production, and sales of testing equipment. It has been engaged in the electrical testing industry for many years, and its products are of high quality. We welcome customers to come and purchase. Service hotline: 0086-27-81778799, to learn more, visit the official website: www.kvtester.com